“Regularly breathing these dusts over a long time can therefore cause life-changing lung diseases.”

Silica(Si02) or crystalline silica is a colorless or white crystal is a common mineral found in the earth’s crust. Materials like sand, stone, concrete, and mortar contain crystalline silica. It is also used to make products such as glass, pottery, ceramics, bricks, and artificial stone.

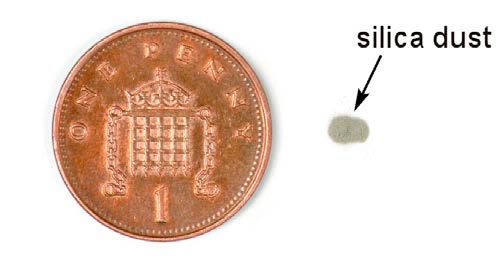

Respirable crystalline silica – very small particles at least 100 times smaller than ordinary sand you might find on beaches and playgrounds – is created when cutting, sawing, grinding, drilling, and crushing stone, rock, concrete, brick, block, and mortar. The largest amount of silica someone should be breathing in a day after using the right controls is shown below next to the penny.

Workers who inhale these very small crystalline silica particles are at increased risk of developing serious silica-related diseases, including:

- Silicosis, an incurable lung disease that can lead to disability and death

- Lung cancer

- Chronic obstructive pulmonary disease (COPD); and

- Kidney disease

To protect workers exposed to respirable crystalline silica, OSHA has issued two respirable crystalline silica standards: one for construction, and the other for general industry and maritime.

These standards tell employers what they need to know to prevent or adequately control construction dust risks. It also provides advice for safety representatives and workers.

- Silica dust – created when working on silica containing materials like concrete, mortar and sandstone (also known as respirable crystalline silica or RCS);

- Wood dust – created when working on softwood, hardwood and wood-based products like MDF and plywood;

- Lower toxicity dusts – created when working on materials containing very little or no silica. The most common include gypsum (eg in plasterboard), limestone, marble and dolomite.

lungs with silicosis

Anyone who breathes in these dusts should know the damage they can do to the lungs and airways. Some lung diseases, like advanced silicosis or asthma, can come on quite quickly.

- Task – the more energy the work involves, the bigger the risk. High-energy tools like cut-off saws, grinders and grit blasters produce a lot of dust in a very short time

- Work area – the more enclosed a space, the more the dust will build up. However, do not assume that dust levels will be low when working outside with high-energy tools

- Time – the longer the work takes the more dust there will be

- Frequency – regularly doing the same work day after day increases the risks.

Before work starts, look at ways of stopping or reducing the amount of dust you might make. Use different materials, less powerful tools or other work methods. For example you could use:

- adequate for the amount and type of dust – RPE has an assigned protection factor (APF) which shows how much protection it gives the wearer. The general level for construction dust is an APF of 20. This means the wearer only breathes one twentieth of the amount of dust in the air;

- suitable for the work – disposable masks or half masks can become uncomfortable to wear for long periods. Powered RPE helps minimise this. Consider it when people are working for more than an hour without a break;

- compatible with other items of protective equipment;

- fits the user. Face fit testing is needed for tightfitting masks;

- worn correctly. Anyone using tight-fitting masks also needs to be clean shaven.

Remember: RPE is the last line of protection. If you are just relying on RPE you need to be able to justify your reasons for this.

#SAFETYONPURPOSE