Every year heavy equipment operators, ground workers and pedestrians are injured or killed by heavy mobile equipment used in construction. Many of these incidents are the result of rollovers or by individuals being struck or crushed by equipment. In fact, “struck-by” deaths are one of the construction industry’s “Fatal Four” leading causes of death on the job site—of which 75% involve heavy equipment.

Several conditions can contribute to struck-by injuries and fatalities, including:

- Falling materials and loads.

- Equipment operator blind spots.

- An operator dismounting and leaving equipment in gear, or not setting the brakes or wheel chocks.

- Equipment tip-over or rollover.

- Equipment or controls not locked out during maintenance.

Administrative Controls

While the best way to stay safe is to stay aware, contractors can help reduce the dangers and help minimize injuries and fatalities associated with heavy equipment by incorporating a few administrative controls at the job site.

ESTABLISHING A HEALTHY WORKPLACE AND SAFE PRACTICES

When pre-planning your projects, consider these measures to help reduce the risk of injuries when working around and using heavy equipment:

Use trained and, where required, certified equipment operators and spotters.

- Provide heavy equipment hazard awareness and safe work practices training to workers.

- Provide a copy of/access to the operating manual for machinery to the operator.

- Develop a path site plan for vehicles, heavy trucks and deliveries to help avoid or limit vehicles and equipment backing up.

- Set up a limited-access zone or swing radius around heavy equipment.

- Provide equipment with rollover protective structure (ROPS).

- Maintain equipment to be in good operating condition.

- Before any equipment maintenance is performed, utilize lockout/tagout procedures.

- Provide a cab shield or canopy worker protection for top-loading vehicles.

- Increase visibility and lighting for night work.

Spotters

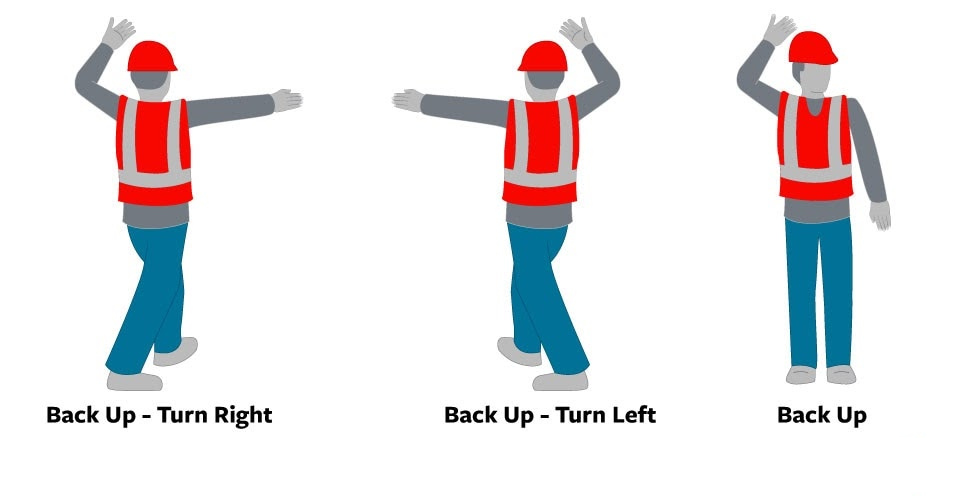

Worker visibility and visual and verbal communication play an important role in ongoing safe operations. Blind spots can be a significant operator issue. A spotter, trained in hand signals, can help provide safety guidance and communication between the operator, workers and nearby pedestrians to compensate for blind spots.

Spotters should wear high-visibility clothing and stand clear of equipment so they are visible to the operator at all times.

Operator Safe Work Practices

In addition to being trained and familiar with the equipment being operated, operators can help reduce the risk of injury or fatality associated with heavy equipment through safe practices.

- Be familiar with the equipment and the operator’s manual.

- Inspect the equipment at the start of each shift, including the brake system, headlights, taillights, brake lights, windshield wipers and audible warning devices, such as the horn and the back-up alarm.

- Adjust all side and back mirrors to help compensate for blind spots.

- Ensure workers are clear of equipment before operating.

- Acknowledge and allow safe passage to workers who alert you that they are approaching.

- Avoid operating equipment parallel to slopes or embankments.

- Turn off the engine and engage brakes before leaving equipment.

- Face the equipment, maintaining three points of contact, while getting on and off the equipment.

- Always wear the seat belt.

- Avoid overloading vehicles.

- Top loading vehicles must have cab shields and canopy protection.

Additional risks can include contact with overhead energized utility lines by mobile cranes and poor ground conditions.

Ground-Worker Awareness and Safe Work Practices

Ground workers also play an important role to help minimize the risk of heavy equipment-related injury.

- Wear high-visibility clothing when working around heavy mobile equipment.

- Avoid positioning themselves in a blind spot or riding on moving equipment.

- Avoid setting up their work area near heavy mobile equipment. The operator may not see them if they are bending over to work or grab a tool.

- Avoid walking or working under a suspended load.

- Make eye contact with and alert the operator—and ensure the operator sees you—before approaching a vehicle.

- Ride only in approved seats and wear a seat belt.

Construction workers are around heavy equipment every day, and they can become accustomed to the presence of heavy equipment, not giving much thought to the risks. Taking some time to understand and follow safety rules—and staying alert while on the job—can help construction workers stay safe.

#SAFETYONPURPOSE